We use world-class steel construction with excellent mechanical properties, reinforced with elements such as Nickel, Chrome, Molybdenum, Niob, which are specially produced at the factory, resistant to rust and corrosion.

All steel structures and components are hot-dip galvanized (NEN-EN-ISO 1461).

All metric fasteners of the steel structure are hot-dip galvanized (NEN- EN- ISO 10684).

Due to the condensation inside the greenhouse, drops occur on the roof bars, gutters and roof ridge beams. This creates a risk of disease for plants. To prevent this, we use a specially designed condensation chute. Thus, the droplets are channeled into the condensation grooves and discharged to the outside.

The heating system includes the following elements:

• Underground Pipes

• Under Groove Heating

• Floor Heating (Pipe Rail)

• Plant Heating

• Roof Heating

• Boiler System (Natural Gas boilers, solid fuel boilers) • Burner

• Vernit Nitrogen system

• Circulation Pumps

• Greenhouse Pump Groups

• Heat Storage Tank (Buffer Tank)

• Pump Groups

Research and many years of experience have concluded that an increase in CO2 levels in the air has a positive effect on plant and fruit growth:

• CO2 increases vegetative development.

• It reduces the risk of fungal and bacterial pathogens in the environment.

• It provides better browning of fruits.

• Increases the aroma of fruits.

In this sense, we enter the gas produced by the condensers installed in the boilers into the greenhouse with CO2 dosing units.

So we will create efficiency and quality in production.

In order to get the best quality and most efficient product from the greenhouse, we design an ideal irrigation system according to the climate data and the type of product to be grown. In order to use water and promote fertilization in the most efficient way, we recycle the excess fertilizer water that the plant does not receive into the system with the drainage system.

We control all the systems in the greenhouse (shadow heat screen, greenhouse ventilation system, fan system, heating system, fog system and irrigation system) with the climate control system. In addition, using an android or computer, you can monitor the current data and partially interfere with the system.

The irrigation and automation system includes the following elements:

• Drainage System

• Irrigation Machines

• UV system

• Osmosis System

• Steel Water Stock Tanks

• Climate Control Unit

• Fertilizer Tanks

We calculate the amount of additional artificial light needed for the plant, taking into account the daily light intensity data of the region. We design the artificial lighting system in accordance with the construction structure of the greenhouse.

We carefully select the luminaires with their high efficiency, easy assembly and disassembly, long life, harmless to the environment and human health, unaffected by negative conditions in the greenhouse environment, and homogeneous reflective properties.

• LED technology

• High pressure sodium lamps

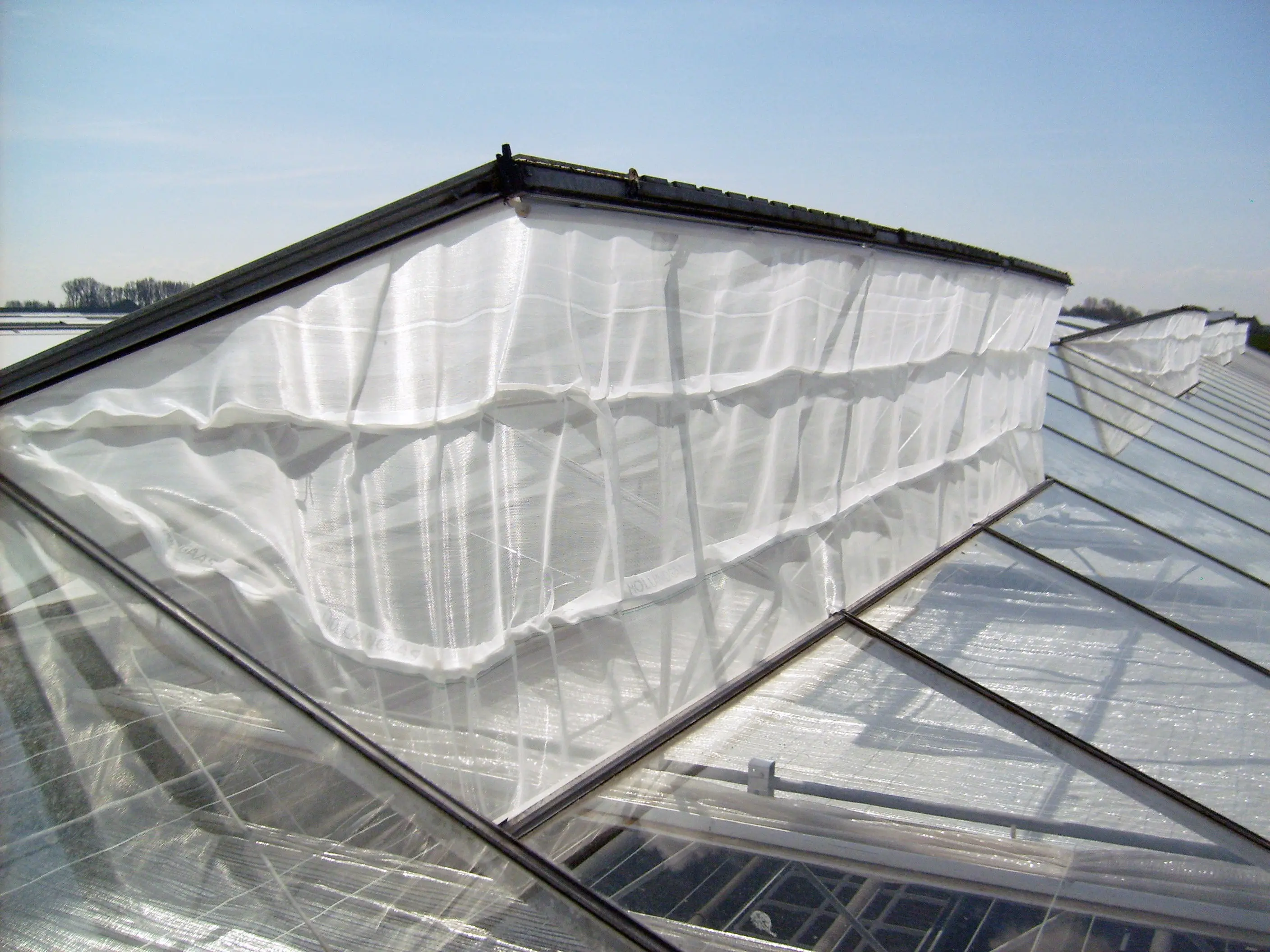

We cover the top and side walls of the greenhouse with curtains in order to control the light and humidity in the greenhouse and to save energy. We determine the shading and energy conservation rate of the curtain fabric according to the climate structure of the region.

We are producing hydroponic and hanging system vegetables in modern smart greenhouses. We use a gutter system made of 0.6 mm sheet metal with 60 cm opening, painted on both sides, suspended on greenhouse trusses for rock wool, perlite and cockpit applications as a soilless medium.

We determine the demand and installed power required for the systems used in the greenhouse, and accordingly, we design and project the electrical system completely:

• Sector control panels

• Main distribution boards - Cables

• Pans

• Transformers

We install circulation fans to circulate the air in the greenhouse and to create a homogeneous air at every point of the greenhouse.

We cover the ground of the greenhouse with a UV-added ground cover made of HDPE in order to prevent the emergence of weeds and to prevent the plants from contacting the soil.

We use long-lasting fly netting made of HDPE with 50 mesh pores to protect it from harmful insects and creatures in the greenhouse.

We supply the tools necessary for plant cultivation in order to have an easy and fast harvest in the greenhouse.

In order to increase the quality and efficiency of the product, Greenglass designs cooling systems specific to the region where the greenhouse will be built, taking into account the climatic data of the region.

For this, we use the following technological systems:

• Cooling Pad and Fan System

• Fog system (High pressure and low pressure)

From the production of perishable agricultural products such as fresh vegetables and fruits, animal products and aquatic products.

They should be stored in cold environments starting from the beginning until consumption. Each product pattern has a different temperature requirement and therefore a different storage technique; In order to preserve the freshness of the products on the first day and to preserve them for a long time, cold stores should be designed according to the product pattern. In this sense, Greenglass with its Partner Company, uses the most accurate storage techniques to determine the climate of the region.

Builds turnkey warehouses according to its structure:

• Designs cold storages,

• Procures materials and equipment,

• Performs on-site assembly with its expert team.

• Activates the systems,

• Performs technical training of the personnel who will work in the warehouse.

• Technical information on storage conditions by our experts during a storage season and provides consultancy services.